PrixMax Radiator Flush Engine Cooling System Cleaner Concentrate

AU From $16.00

or 4 payments of $4.00 with

Learn more

Learn more

We sell a lot of coolant and are experts in the industry, so much so we put it in our name. Based in Townsville we have since 1997 been bulk supplying over 100,000L of coolant a year to major mines in Australia and PNG right through to small package supply to backyard mechanics. Along the way we have you learnt a thing or two about coolant and we have heard every furphy, misconception and misunderstanding in the industry. There is a lot of bad information out there about coolant and we want you to make an educated decision with the right information. With major engine manufactures agreeing that up to 40% of engine failure is attributed to cooling system failure, can you afford not to get the very best advice from FCP Solutions, your experts in all things coolant.

The following is some common coolant terminology you will read about in the questions and answers below, this will help you better understand the content.

An engine coolant has two main roles:

Technically speaking, coolant in a liquid cooled cooling system is the fluid that transfers the heat from the internal combustion engine. Now this could be a great number of liquids that have the ability to transport heat, but they maybe extremely volatile in certain environments or have an adverse effect on the internal components over time. With that being said it is then important to select the liquid that will perform this task at optimum efficiency, price, minimum volatility in that environment, freeze point and a host of other considerations.

An engine coolant therefore typically comprises a base fluid, which is responsible for transferring the heat (and, if required, protecting against freezing), and an additive package, which is responsible for protecting the system against corrosion and provides other performance advantages. Given the two requirements of transferring heat and protecting the system, we can classify engine coolants by their base fluid, and by their additive technology package.

Coolant cools an engine by heat transfer, which is the process of transferring heat between physical systems . An engine produces heat during combustion, which must be released or the heat will build up and cause the engine to fail if there is no way to remove it. In a liquid-cooled system, coolant transports heat from the engine to a heat transfer medium, such as the radiator, where the heat is dissipated and released.

The cooling system operates by continuously flowing liquid through the engine block's channels. The coolant is forced through the engine block with the help of the water pump. The heat from the engine is absorbed by the solution as it flows through these tubes. The heated liquid flows to the radiator, where it is cooled by air blown through the grills as it passes through, before being returned to the engine to restart the process.

Understanding this process is critical for selecting the most effective fluid for eliminating heat from an engine, allowing it to function in it’s most efficient state and therefore prolonging it’s life.

A corrosion inhibitor package or additive is the type of additive used to stop corrosion. Generally speaking there are three main types of coolant technology, Conventional Chemistry, Hybrid and Organic. Hybrid and Organic are the most common type available today and can be found as factory fill in almost all new engines. Conventional chemistry coolants are still available in the market today but are slowly being phased out or replaced with hybrid and organic as they offer much better protection and for longer periods of time as well as numerous other advantages.

Traditional (or conventional) coolants are formulated with mineral (inorganic) inhibitors such as phosphates, silicates, borates, nitrite and other components. Different conventional coolants will contain different combinations of these inorganic inhibitors to provide the corrosion protection required. These inhibitors have relatively short service lives so require more regular monitoring and change-out.

Hybrid technology coolants utilise a combination of mineral inhibitors and organic additive technology (OAT) inhibitors to protect against corrosion. The combination of inhibitor technologies is broadly driven by regional preferences. For example, Japanese and Korean OEMs prefer the use of phosphates over silicates, whereas European OEMs prefer silicates over phosphates.

Organic additive technology (OAT) coolants contain only “organic” inhibitors that are virtually non-depleting when compared to traditional inhibitors. Coolants based on OAT inhibitors offer extended life corrosion protection and benefits from a compatibility perspective. OAT inhibitors work by creating a thin molecular layer at the corrosion sites, and – unlike traditional inhibitors – are not chemically consumed as they perform the function of preventing corrosion.

How Each Inhibitor Protects The Metal

The advent of organic inhibitor technology (OAT) for engine coolants has allowed engines to be constructed from lighter weight alloys in the drive for greater heat transfer performance and operating temperature efficiency, and has also significantly increased engine coolant service intervals. Coolants based on OAT inhibitors will protect the engine for much longer service intervals compared with conventional inorganic inhibitor technologies, because they protect the system against corrosion in a different way.

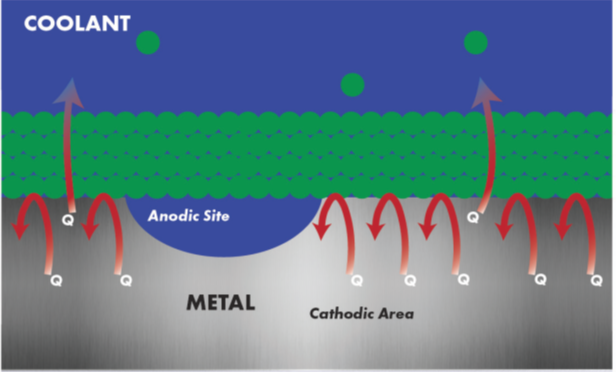

The following diagram shows how traditional / mineral inhibitor packages function in a cooling system. These inhibitors work by forming a blanket protective layer covering the inside surfaces of the cooling system, which is represented by the green layers in the diagram. This protective layer is broken down over time as the chemical inhibitor package is depleted or spent. It also limits heat transfer capacity given it “blankets” the surface of the cooling system metals. After a certain period of time (the service life) – for example, 1-2 years – there is no longer enough traditional mineral inhibitors left in the coolant to continue to repair the layer (ie prevent corrosion) and the coolant must be changed out.

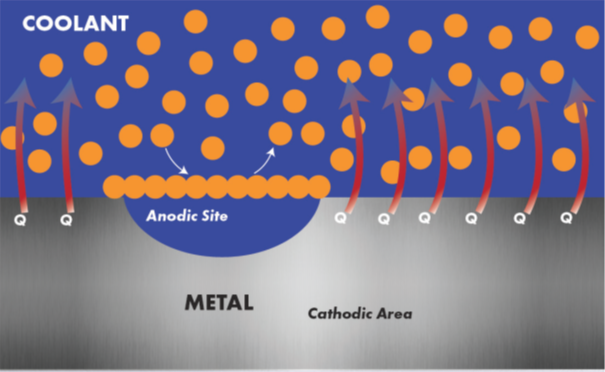

Organic OAT inhibitor packages function in a different manner. Rather than forming a blanket layer of inhibitors on the metal surface to protect against corrosion, OAT inhibitors form a selective monomolecular layer on the metal surface only at the anodic sites (the active corrosion cells). This monomolecular layer is extremely strong, providing excellent protection against cavitation and corrosion. In comparison to mineral inhibitor technologies, the chemical protection layer formed by the OAT inhibitors does not get thicker with time because the chemical action ceases when the appropriate areas of the metal are coated, and the service life of the coolant is significantly extended as the inhibitors are virtually non-depleting as they perform the act of preventing corrosion. Further, due to the fact that the chemical protection layer is not a solid blanket layer of inhibitors, OAT-based coolants exhibit much greater heat transfer performance when compared with inorganic inhibitor-based coolants.

How well any of these inhibitors perform their role can be affected by a number of other forces, such as the topping up of fluid with water which dilutes the inhibtor concentration so it can't perform it's role adequately. These activities can have a major impact on the life of the engine and cause costly premature maintenance and downtime. It is vitaly important to maintain inihibtor levels to fluid manufacturer recommended concentration levels to ensure trouble free service life.

This Liner is in poor condition showing severe pitting and cavitation damage. During routine strip down maintenance this significantly increases the costs and downtime.

This Liner is in poor condition showing severe pitting and cavitation damage. During routine strip down maintenance this significantly increases the costs and downtime.

This Liner shows no signs of pitting or cavitation, attributed to the excellent performance of PrixMax coolant in heavy duty systems. During routine strip down maintenance this significantly decreases costs and downtime.

This Liner shows no signs of pitting or cavitation, attributed to the excellent performance of PrixMax coolant in heavy duty systems. During routine strip down maintenance this significantly decreases costs and downtime.

A coolant base fluid is responsible for transferring the heat and the type of base fluid will determine the heat transfer properties of the coolant. The base fluid may also alter the freezing point and boiling point of the fluid, which is why you might see the terms “anti-freeze” and “anti-boil” when referring to coolants. In cold climates, the requirement to protect against freezing temperatures is an important one, but those temperatures are not often seen in Australia. In a closed cooling system, most of the protection against boiling temperatures comes from the fact that the system is maintained under pressure (a function performed by the radiator cap), which raises the fluid’s boiling point.

In general, engine coolants can be characterised by the following base fluids:

Water by itself is the best cooling liquid for the removal of heat from an engine. Like all base fluids however, including glycols, a corrosion inhibitor additive package needs to be added to water in order to prevent corrosion in the system over time.

Where protection against freezing is required, the base fluid will need to contain an anti-freeze agent such as ethylene glycol or propylene glycol which, when added to water, lowers the freezing point of the fluid. There is a trade-off though, as the glycol solution is less effective at transferring heat than pure water. A 50/50 mix of ethylene glycol and water will have a freeze point of around -37°C. Like with plain water, a corrosion inhibitor additive package still needs to be added to the glycol/water mixture in order to prevent corrosion over time.

Although nearly all engine coolants contain water in some concentration, the term “water-based coolant” generally refers to coolants that do not contain an anti-freeze base fluid such as ethylene glycol or propylene glycol. Water-based coolants utilise water as the primary base fluid to transfer heat in the engine.

Water-based or “glycol-free” coolants can be used in climates where the temperature does not drop below 0°C – in other words, where protection against freezing is not required.

In Australia, our industry standard for automotive and light duty engine coolants, Australian Standard AS 2108-2004, recognises that coolants may not contain anti-freeze. Under this standard, these coolants are referred to as “Type B” coolants.

In climates where freeze protection isn’t required, these water-based coolants offer many advantages over their anti-freeze based counterparts, including:

Water based coolants are now OE approved by some major manufacturers with PrixMax’s legacy product RCP formally approved by Detroit MTU and Mercedes Daimler.

Waterless Coolants are generally 90% to 95% antifreeze EG or PG with the with remainder being inhibitor package with it’s concentration depending on the inhibitor grade, type and intended application.

Waterless coolants are a very poor performing coolant with regards to cooling capacity because of the elimination of water all together. While it can be claimed that this reduces corrosion attacks it is far more beneficial to choose a high quality inhibitor package mixed with water to take advantage of the superior heat transfer properties of water. To date no OEMs allow the use of waterless coolants in their engines. There are significant disadvantages from a heat transfer perspective, and engines and cooling systems have been designed to operate within certain temperature ranges that may not be met if using a waterless coolant.

FCP Solutions does not sell waterless coolants at all based on their very poor cooling capacity and prohibitive cost over a large volume.

Antifreeze Anti boil coolant is a term used to describe an engine coolant that contains an Antifreeze chemical such as EG or PG as the base fluid. There are some other less common fluids such as glycerine that has been used as alternative to EG and PG. The Antifreeze chemical generally makes up to 50% to 33% of the overall concentration of antifreeze based coolant with remainder inhibitor package 5% to 10% depending on the inhibitor grade, type and intended application and the remainder water.

Under the Australian Standard AS 2108-2004, coolants which offer a certain level of freeze protection through these base fluids are referred to as “Type A” coolants.

Anti-freeze agents such as EG and PG must still be diluted with water if they are to provide the appropriate level of freeze protection and heat transfer. This is why engine coolants supplied in “concentrate” form must be diluted with good quality water before use, typically to a concentration of between 33% and 67% in water.

Both EG and PG have their own set of chemical properties and when you add them to water, and depending on the concentration you add them, you impart those chemical properties onto water. This changes how water as a base fluid behaves. Water base coolants have a host of benefits vs there glycol base counterparts.

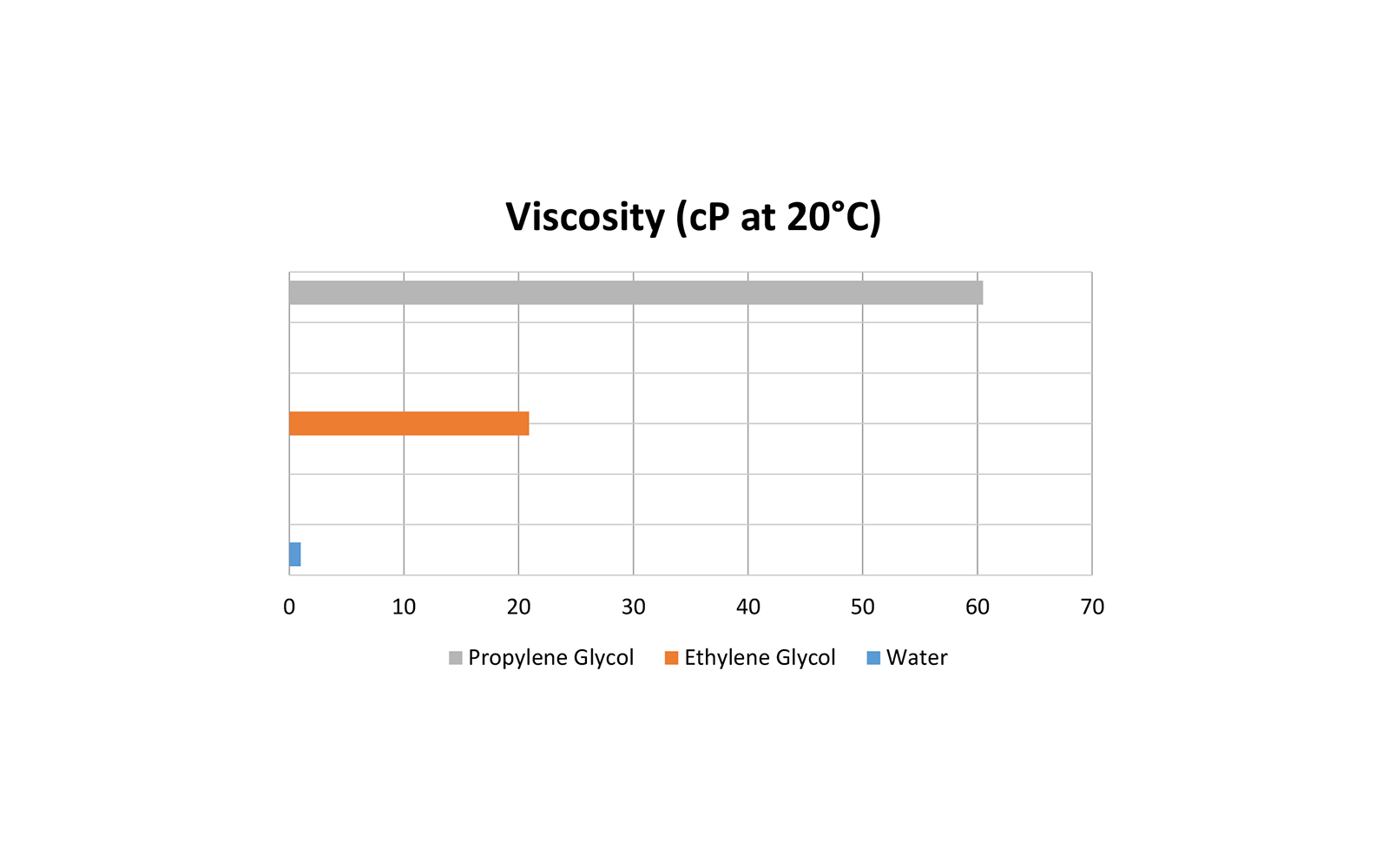

The viscosity of water is much lower than EG and PG, with EG being around 20 times more viscous and PG around 60 times more viscous than water. This means increasing the viscosity of the cooling fluid directly increases power consumption by affecting pump horsepower and fluid flow. Water based coolants are able to flow more quickly around the cooling system and transfer heat away faster. The table to the left displays the various viscosity properties of water, EG and PG.

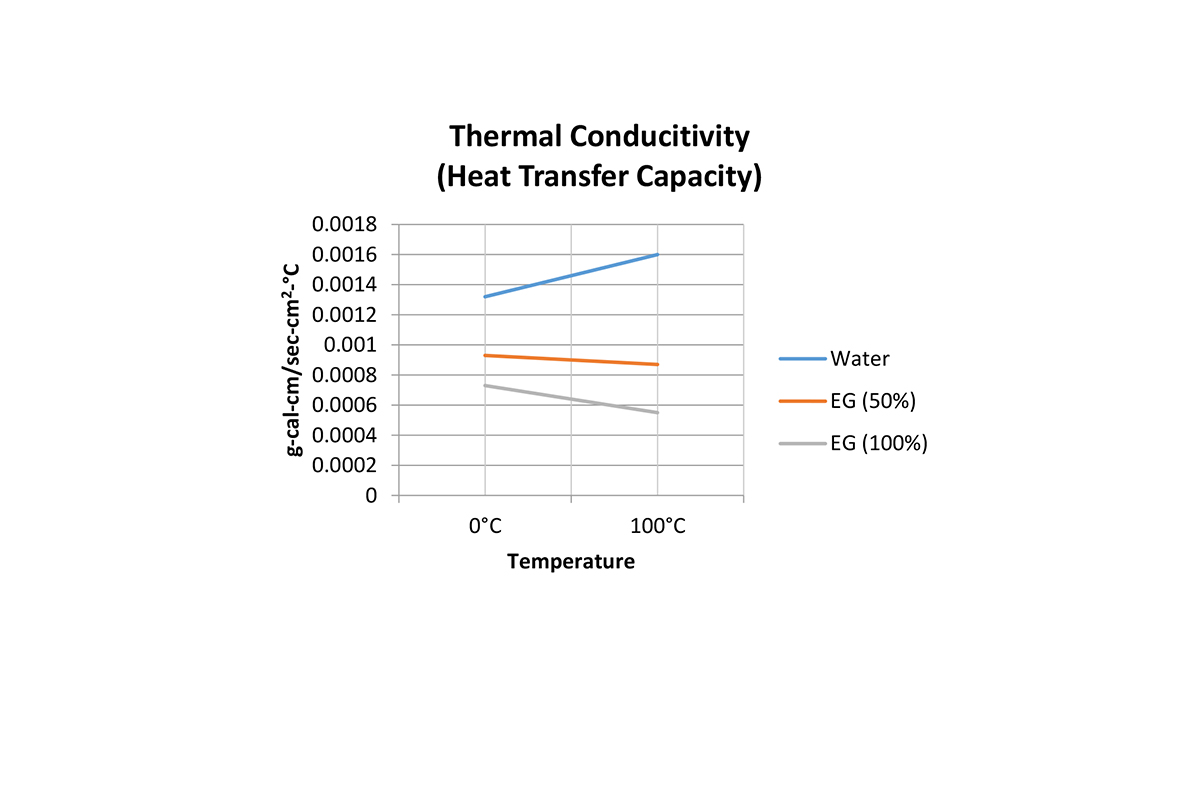

The thermal conductivity of a fluid refers to its capacity for heat transfer. In a temperature rage of 0°C to 100°C, a 50% volume EG based coolant (as found in a typical anti-freeze coolant) is anywhere between 25 to 49% less efficient at transferring heat than a water based coolant. Furthermore Water becomes more efficient at removing heat the hotter is gets where as an EG coolant becomes worse, as seen in table on the right.

Water has a higher specific heat capacity than EG and PG which means water can absorb energy much more readily and thereby more effectively remove heat. Please see the table on the left.

.jpg)

A regularly cited reason for using an aqueous glycol formulation for engine coolants rather than formulated water is the fact that aqueous glycol solutions have an elevated boiling point relative to water. However, while a glycol based coolant does contribute to an elevated boiling point (the boiling point of a 50% by volume glycol based coolant is around 8°C greater than pure water), the mian increase comes from having a system operating under a higher pressure than atmospheric pressure. Even putting aside the superior heat exchange benefits of water based engine coolants (which would effectively negate the higher boiling point of a glycol based fluid because engines run cooler to begin with), the 121°C boiling point of water in a pressurised system remains higher than the normal operating temperatures of most engines (which is typically between 82°C and 105°C). It is important, then, to ensure that the engine is equipped with a properly functioning radiator pressure cap to increase the boiling point of the cooling fluid (and also increase the efficiency of the water pump).

The much more important value in the cooling system than the fluid's boil point is its ability to carry heat energy out of the engine to the radiator. As can be seen above pure water has a much higher specific heat capacity than both EG and PG, and is one of the most effective coolants that could possibly be used. When mixed with an effective corrosion inhibitor such as RCP Platinum, water provides the ultimate in cooling system performance

Of course, if operating in an environment where freezing temperatures are encountered, the only choice is to use an anti-freeze based coolant. However, if operating in a warm environment like most of Australia, it is far more beneficial to use a water-based coolant.

FCP Solutions have long been an advocate for the removal of glycol from engine coolant where the environment allows it. We will still recommend and supply glycol based coolant where there is an operating need, but for the most part, glycol free is the superior choice. The benefits not only include performance benefits as illustrated above, but a raft of operational and safety benefits including:

As mentioned before, both EG and PG are class 1 combustibles and by replacing glycol base coolants with a water base coolant you eliminate the potential fire hazard all together. Glycol has been banned from a number of operating environments because of it's flammability including drag strips. K-Chem Labratories a forensic lab specialising in discovering the truth behind fires has published an article on the flammability of glycol that can be read further below.

Click Here to Read K-Chem Technical Data Sheet on Antifreeze Fires!

Below is a video of an experiment PrixMax conducted to demonstrate the flammability of glycol based engine coolants

Glycol based coolants or Type A coolants are factory fill for nearly all manufacturers across the planet, for the simple reason that they don't know if the cooling system will be exposed to freezing temperatures, because they often don't know where the machine will be shipped. By factory filling with glycol based coolant this covers the manufacturer across the globe, even though it may not be the best for the machine in a particular environment. If the user knows that the machine won't be exposed to prolonged and harsh freezing conditions the far superior choice is a water based or Type B fluid to benefit from it's greater cooling capacity and many other benefits already explained above.

Water based coolants are now OE approved if the engine is operating in a temperate climate by some major manufacturers including Caterpillar, Detroit MTU and Mercedes Daimler. These OE's often don't promote the products themselves as often the staff at the dealer level simply don't understand the difference in the products enough to explain the benefits to the customer and more often than not they are considerably cheaper, so at a dealer level it looks better for their bottom line if they are invoicing out higher value items. PrixMax’s legacy product RCP is formally approved by Detroit MTU and Mercedes Daimler.

Coolant colour comes from the dye added by the coolant manufacturer and should not be used to distinguish the type of coolant.

Certain OEMs may dictate a certain colour requirement in their coolant specifications, however the colour does not identify the chemical and technical properties of the coolant. Given that both OEMs and coolant manufacturers themselves have their own colour schemes, there is no colour “standard” across the industry. This means that, for example, two coolants which may both be coloured red nevertheless have different chemical make-ups.

It is therefore important to understand the type of coolant that is in the system from a technology perspective (eg OAT, hybrid, or inorganic), rather than simply noting the colour as it is not a reliable guide.

Firstly, there is a common misunderstanding in the industry that if you have a water filter on your engine that you don't require coolant, as the coolant is in the water filter. This is completely FALSE and these operators will spend considerably more amount of time and money fixing coolant related issues in their equipment, due to a significant imbalance in the cooling chemicals. These water filters are an SCA filter, which stands for Supplementary Coolant Additive and the key to that being supplementary. SCA were a common alternative to changing the traditional coolant every 1-2 years was to add more of the mineral inhibitor package into the cooling system in the form of an SCA. An SCA is a chemical package that is added to the coolant either as a liquid, powder, or as a charge via a coolant filter. The package is designed to replenish the depleted mineral corrosion inhibitors, control the pH balance of the coolant and protect the system from the build up of harmful deposits until the next service interval.

If OAT coolants are in service there is no requirement to use SCA's or chemically charged water filters. The introduction of OAT-based coolants simplifies maintenance requirements, as there is no need to top-up with SCAs either via liquid additive boosters or charged coolant filters. In fact, adding these traditional technology chemicals via SCAs to a modern OAT coolant in the system can potentially negatively affect the service life of the coolant, as excessive SCA levels can lead to the build up of particles and deposits in the system which can cause damage to components such as water pumps and heater cores.

When transitioning from an older, traditional technology coolant to an OAT coolant, it is important to educate maintenance technicians about the new technology. This will enable them to understand the benefits of the new technology coolant and the maintenance practices required to achieve the coolant's maximum service life. When utilising OAT coolants, the requirement to use and stock liquid SCAs and charged filters is eliminated entirely, resulting in cost savings for the customer. Where coolant filters are fitted, a blank filter containing no chemical additive package can be used. If required, cooling system top-ups should only be performed using a pre-mixed version of the relevant OAT coolant, rather than with SCAs or plain water.

With the advent and broad OEM acceptance of OAT-based engine coolants, SCAs have become somewhat of a relic of earlier coolant technologies. Where traditional coolant technologies are in use, SCAs continue to serve an important function in boosting and maintaining the traditional coolant's chemical additive package between service intervals; however, these days, operators have the option of using more modern coolant technologies that eliminate the need for SCAs. Today, OAT-based engine coolants enable cooling systems to operate more efficiently, with significantly less on going maintenance requirements (and costs), and offer far greater service intervals than traditional coolant technologies. There is simply no longer a need to add potentially harmful mineral inhibitors via SCAs and charged filters when using an advanced technology OAT coolant.

FCP Solutions are North Queensland distributors of PrixMax engine coolants since 1996. PrixMax is a recognised leader in the coolants market and has been developing and manufacturing premium quality coolants in Australia since 1994. Operating out of a specialised manufacturing facility that is accredited against international standards such as ISO 9001:2015 and ISO 14001:2015, PrixMax is committed to developing leading technology products to suit any vehicle and application. The company also operates one of Australia’s only dedicated coolant testing and research laboratories, where they focus on providing state-of-the-art quality products backed up by industry leading technical support.

In the 1990s PrixMax pioneered the release of organic additive technology coolants in Australia with their long life organic coolant product range comprising the water-based product known as RCP (Radiator Corrosion Protector) and the anti-freeze product MEG95. Since then PrixMax's long life coolants have become arguably the most extensively field tested products of their kind in Australia recording literally hundreds of thousands of hours of successful performance in the field across a wide range of Original Equipment Manufacturer (OEM) engines. Today PrixMax continues to engineer innovative coolant solutions to meet the increasingly complex demands of modern engine cooling systems.

In the 1990s PrixMax pioneered the release of organic additive technology coolants in Australia with their long life organic coolant product range comprising the water-based product known as RCP (Radiator Corrosion Protector) and the anti-freeze product MEG95. Since then PrixMax's long life coolants have become arguably the most extensively field tested products of their kind in Australia recording literally hundreds of thousands of hours of successful performance in the field across a wide range of Original Equipment Manufacturer (OEM) engines. Today PrixMax continues to engineer innovative coolant solutions to meet the increasingly complex demands of modern engine cooling systems.

PrixMax Radiator Flush Engine Cooling System Cleaner Concentrate

AU From $16.00

or 4 payments of $4.00 with

Learn more

Learn more

PrixMax Euro Ultra Extended Life Antifreeze Antiboil Concentrate For VW & Others

AU From $22.00

or 4 payments of $5.50 with

Learn more

Learn more

PrixMax MEG HT Long Life Universal Antifreeze Antiboil Hybrid OAT Coolant Concentrate

AU From $20.00

or 4 payments of $5.00 with

Learn more

Learn more

PrixMax MEG95 Premium Universal Antifreeze Antiboil OAT Coolant Concentrate Or Premix

AU From $20.00

or 4 payments of $5.00 with

Learn more

Learn more

PrixMax RCI Universal Non Antifreeze Conventional Chemistry Coolant Concentrate

AU From $10.95

or 4 payments of $2.74 with

Learn more

Learn more

PrixMax RCP Platinum Premium Universal Non Antifreeze OAT Coolant Concentrate or Premix

AU From $30.00

or 4 payments of $7.50 with

Learn more

Learn more

PrixMax RCP+ Long Life Universal Non Antifreeze Hybrid OAT Coolant Concentrate

AU From $20.00

or 4 payments of $5.00 with

Learn more

Learn more